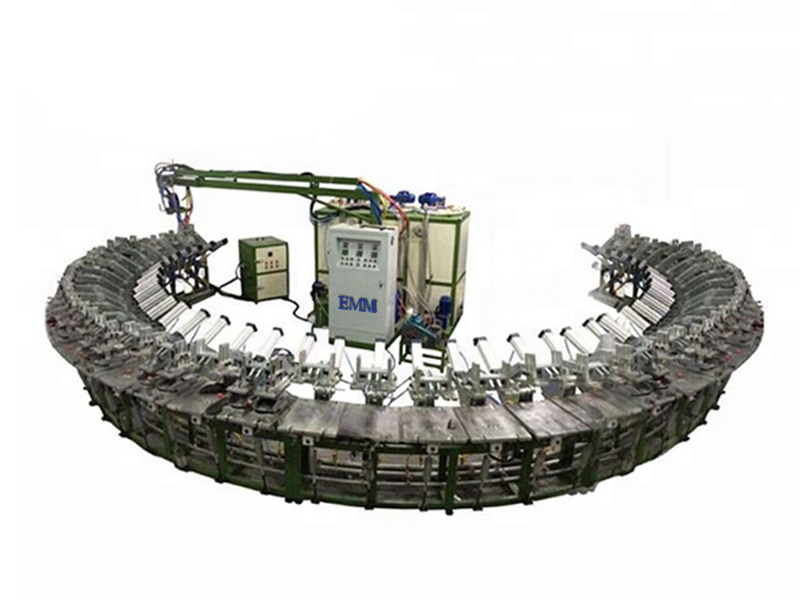

ciągła linia do produkcji pianki poliuretanowej styropianu eps

This machine advantage:

1,High capacity : 45-60sec./cycle for easy EPS products, 70-100 seconds/cycle for big products.(open/close the mould,baiting,cooling)

2,save steam: this machine adopts allenbach big flow with low pressure, it can save 1/4 steam compare other factory.

3,high quality: moving parts use durable sleeve made in Japan, main components use word famous brand which can gurantte long service life.

4,multi-function:it can fit both big and small mold

2.Technical data of polyurethane styrofoam eps foam production line

| Pozycja | Unit | ML-1200 | ML-1400 | ML-1750 | ML-2000 |

| Mould dimension | mm | 1200x1050 | 1400x1250 | 1750x1450 | 2000x1650 |

| Max product dimension | mm | 1050x900x420 | 1250x1100x420 | 1600x1300x420 | 1850x1500x420 |

| Stroke | mm | 150-1500 | 150-1500 | 150-1500 | 150-1500 |

| Steam entry | inch | 3"(DN80) | 4"(DN100) | 4"(DN100) | 4"(DN100) |

| Steam consumption | KG/cycle | 5-7 | 6-9 | 8-12 | 9-15 |

| Steam pressure | Mpa | 0.5-0.7 | 0.5-0.7 | 0.5-0.7 | 0.5-0.7 |

| Cooling water entry | Inch | 2.5"(DN65) | 3"(DN80) | 3"(DN80) | 3"(DN80) |

| Cooling water consumption | KG/cycle | 45-130 | 50-150 | 55-180 | 90-220 |

| Cooling water pressure | Mpa | 0.3-0.5 | 0.3-0.5 | 0.3-0.5 | 0.3-0.5 |

| Compressed air entry | Inch | 1.5"(DN40) | 2"(DN50) | 2"(DN50) | 2"(DN65) |

| Compressed air consumption | M3/cycle | 1.5 | 1.8 | 2 | 2.5 |

| Compressed air pressure | Mpa | 0.5-0.7 | 0.5-0.7 | 0.5-0.7 | 0.5-0.7 |

| Drainage | Inch | 5"(DN125) | 6"(DN150) | 6"(DN150) | 6"(DN150) |

| Capacity 15kg/m3 | Second | 60-120 | 70-140 | 80-150 | 100-200 |

| Connected load/power | kw | 9 | 12.5 | 16.5 | 16.5 |

| Overall dimension(LxWxH) | mm | 4750x1750x3130 | 4750x1920x3250 | 4750x2030x3450 | 4750x2240x3680 |

| weight | KG | 5000 | 5500 | 6000 | 7000 |

3. Feature polyurethane styrofoam eps foam production line

1.this EPS machine adopts PLC programmable controller and touch human-machine interface control, advanced foam moulding process,can produce a variety of products.

2.this EPS machine produced a variety of foam products, low moisture content, forming speed, low consumption, size and stability

3.this EPS shape moulding machine executable automatic, semi-automatic and manual operation started in the middle of 4 operation mode,equipped with safety protection devices, can enssure safe and reliable operation.

4.this EPS shape moulding machine uses programmable controllers, touch human-machine interface, executable computer production control management, high degree of automation, simple operation, easy maintenance, labor intensity at the end.

5.this EPS machine adopts the international advanced electrical and hydraulic integration,improve the speed of molding products, a significant reduction in energy consumption and reduce enviromental pollution.

6.this machine uses a variety of heating process, a variety of feeding methods and cooling.

7.this EPS machine vacuum system to accelerate the rate of product effectiveness, reduce cooling time, product moisture content is low.

8.this EPS machine uses the control instruments, eletrical, pneumatic components, valves and other supporting both dometic and foreign high quality brand name products.

9.ML-1400 type EPS foam box shape moulding machine can load 1000-1400mm mold, ML-1750 mold can load 1400-1750mm mold.

10.the aircraft can choose mechanical or hydraulic release models.

-Our services---

1. Value clients, guarantee equipment quality and answer clients’ questions anytime and anywhere.

2. Customizing machines according to clients' inquiry , such as different design, different brand parts, different colors, more function,etc.

3. Engineers go to clients' factory in time for installation , training and trial production .

4. 1 year free warranty, Lifetime technical service support, some spare parts will be send to our customer free of charge.

Szybkie Szczegóły

Rodzaj przetwarzania: Maszyna do spieniania

Stan: nowy

Product Type: Foam Net

Miejsce pochodzenia: Chiny (kontynentalne)

Nazwa marki: EMM

Voltage: 380V/50HZ or customized

Power(W): 9kw-12.5kw

Dimension(L*W*H):4700x1930x3250mm

Weight: 5500KG

Certyfikacja: CE

Warranty: 12 months

Obsługa posprzedażna: Inżynierowie dostępni do obsługi maszyn za granicą

Application:EPS packaging box. icf panel,decoration cornice, fish box, fruit box

Automatic: Full automatic EPS polystyrene foam machine

Material: Steel structure, stainless steel eps foam machine

Special: foam machinery, plastic vacuum forming machines

Raw material: EPS, expandable Polystyrene, Styrofoam, Thermocol

Certificate: CE ISO9001

Control System: PLC+Touch Screen

Machine Type:continuous polyurethane styrofoam eps foam production line

HS code: 84778000 foaming machine

eps machine: EMM continuous polyurethane